If ultrasonic waves hit for example an air inclusion within a sample, a very bright contrast can be detected. Comparable to the resolution of an optical microscope, material defects such as microcracks, inclusions and delaminations can thus be visualized.

We work with the systems of our sister company Analytical Systems GmbH. Based in Westhausen, this company has specialized in high-resolution ultrasonic scanning microscopes for non-destructive material testing for more than 30 years.

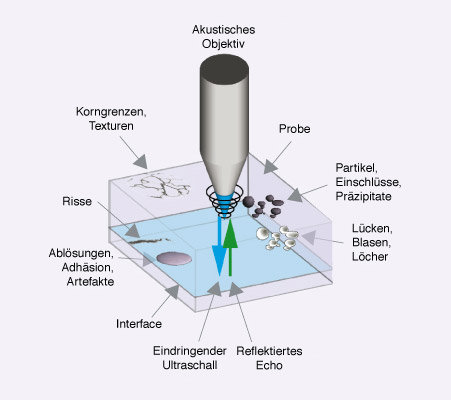

The systems use the pulse-reflection method, also known as the pulse-echo method. The core element of the ultrasonic microscopes is an ultrasonic head consisting of a special acoustic lens and a transducer connected to it - a piezoelectric crystal, which can be made of different materials depending on the frequency range used.

The piezoelectric element is capable of converting electrical signals into sound waves. These are focused and bundled by the downstream lens as acoustic waves onto the object under examination. DI water is primarily used as the coupling medium that transmits the ultrasonic waves to the specimen. These sound waves are finally reflected by the sample back to the transducer and then evaluated by an analog-to-digital converter (ADC) and corresponding software and displayed as a gray-scale image.

Based on a component platform, combined with application specific modules, our sister company PVA TePla Analytical Systems GmbH is able to provide the appropriate system for the desired examination requirement and materials.